Why Understanding the Cost of Plastic Injection Molding is Essential for Your Business Growth

In today's highly competitive manufacturing landscape, understanding the cost of plastic injection molding is not just important—it's essential for sustained business growth. As industry expert Dr. Emily Larson, a leading authority in polymer engineering, notes, "A clear comprehension of the cost structure in plastic injection molding can lead to informed decisions that drive efficiency and profitability." This insight highlights the importance of grasping the economic factors that influence the molding process, from material selection to production volume.

With the increasing demand for high-quality plastic products, businesses must be equipped with knowledge about the cost of plastic injection molding to make strategic choices. Companies that overlook these factors may find themselves at a disadvantage, facing unexpected costs and inefficiencies that can hinder their growth. By carefully analyzing expenditures associated with plastic injection molding, businesses can optimize their processes, mitigate risks, and ultimately enhance their bottom line. Understanding these costs is not merely a logistical necessity; it is a foundational step toward achieving competitive advantage in the ever-evolving marketplace.

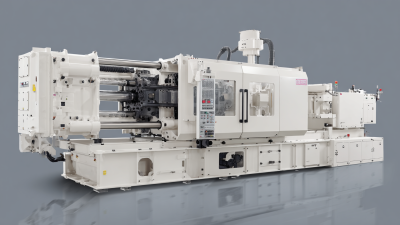

Understanding the Basics: What is Plastic Injection Molding?

Plastic injection molding is a widely used manufacturing process where molten plastic is injected into a mold to create various products. This method is renowned for its efficiency and ability to produce complex shapes with high precision. The process starts with the heating of plastic pellets until they melt, after which the liquid plastic is injected into a pre-designed mold. Once the plastic cools and solidifies, the mold is opened, and the finished part is ejected. This technique is integral to industries ranging from automotive to consumer goods.

Understanding the basics of plastic injection molding is crucial for businesses looking to optimize their production costs and enhance product quality. By grasping how the process works, companies can make informed decisions about mold design, material selection, and production techniques. This awareness not only helps in reducing waste and improving turnaround times but also allows businesses to innovate and adapt their products to meet market demands effectively. In an increasingly competitive landscape, leveraging knowledge of plastic injection molding can lead to smarter investments and drive sustainable growth.

Understanding the Cost of Plastic Injection Molding is Essential for Your Business Growth

| Cost Element | Description | Average Cost ($) | Impact on Business |

|---|---|---|---|

| Material Costs | Cost of raw materials used for injection molding | 1.00 - 5.00 per kg | Directly affects production cost & pricing strategy |

| Tooling Costs | Initial investment for molds and tooling | 5,000 - 100,000 | High upfront cost; amortized over production volume |

| Labor Costs | Costs associated with labor during the production process | 20 - 30 per hour | Influences operational efficiency and margins |

| Overhead Costs | Utilities, rent, and other indirect costs | Variable | Impacts overall profitability |

| Maintenance Costs | Costs related to maintaining machinery and molds | 1,000 - 5,000 annually | Essential for ensuring production quality and efficiency |

Key Factors Influencing the Cost of Plastic Injection Molding

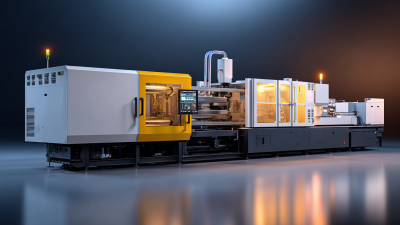

Understanding the cost factors of plastic injection molding is crucial for businesses aiming to optimize their operations and enhance profitability. Key elements influencing these costs include the type of plastic used, the complexity of the mold design, production volume, and the specific machinery employed. With the global injection molded plastics market projected to grow from $403.85 billion in 2024 to $561.58 billion by 2032, at a CAGR of 4.2%, savvy companies must keep an eye on these factors to maintain their competitive edge.

The selection of materials, such as low-density polyethylene, has significant implications for cost. As the low-density polyethylene market is expected to expand from $32.57 billion in 2025 to $50.44 billion by 2032, understanding material costs can help manufacturers make informed decisions related to product development and pricing strategies. Additionally, investments in advanced machinery, like ball screw systems for injection molding machines, can enhance precision and efficiency but also require careful financial consideration. By analyzing these key factors, businesses can effectively plan and manage their resources, driving growth and sustainability in the plastic manufacturing industry.

The Long-Term Financial Impact of Injection Molding on Your Business

Understanding the financial implications of plastic injection molding is crucial for businesses aiming for sustained growth. A comprehensive report by Mordor Intelligence reveals that the global injection molding market is expected to reach $358.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 3.3% between 2020 and 2025. This significant growth highlights not only the demand for injection molded products but also emphasizes the necessity for businesses to optimize their production processes to remain competitive.

The long-term financial impact of injection molding extends beyond initial production costs. According to a study from the American Society of Manufacturing Engineers, reducing cycle times in injection molding can lead to an increase in production efficiency by up to 30%. This efficiency directly translates to cost savings and improved profit margins. Additionally, investing in advanced technologies and processes such as automation can yield a reduction in labor costs by nearly 20%, facilitating better resource allocation. Recognizing and understanding these aspects of injection molding can empower businesses to make informed decisions that foster growth and innovation in their manufacturing strategies.

How to Optimize Your Budget for Plastic Injection Molding Projects

To optimize your budget for plastic injection molding projects, it’s crucial to thoroughly understand the key cost components involved. Initially, focus on material selection, as different plastics carry varying costs and properties that can impact both the budget and the quality of the final product. Conducting a detailed analysis of the required materials against their performance characteristics can help in making more informed decisions, ensuring that you are not overspending on unnecessary enhancements when a more cost-effective option will suffice.

Additionally, consider the design and complexity of your mold. Investing in high-quality design upfront can significantly reduce production costs in the long run. Simplifying complex geometries and minimizing the number of components not only lowers fabrication costs but also optimizes the manufacturing process. By collaborating with experienced mold designers and manufacturers, businesses can strike a balance between functionality and cost efficiency, enabling a smoother production flow and ultimately contributing to better profit margins.

Strategic Planning: Anticipating Costs for Business Growth in Injection Molding

Understanding the costs associated with plastic injection molding is crucial for businesses looking to grow strategically. As companies navigate the complexities of production, anticipating costs enables them to budget effectively and allocate resources efficiently. For instance, with the CNC video measurement market projected to reach $157.11 million by 2030, businesses involved in injection molding must recognize the impact that measurement technologies can have on their operational costs.

By incorporating advanced measurement solutions, firms can enhance quality control and minimize waste, leading to significant long-term savings. This foresight not only helps in optimizing production processes but also positions companies as competitive players in a rapidly evolving market. As growth in related sectors continues to rise at a compound annual growth rate of 6.9%, being mindful of costs will allow businesses to make informed strategic decisions that support their expansion efforts in the injection molding industry.

Understanding the Cost of Plastic Injection Molding

Related Posts

-

7 Amazing Benefits of Plastic Injection Molding You Didn't Know

-

Understanding the Essential Functions of Plastic Injection Machine Parts in Modern Manufacturing

-

How to Optimize Your Production Process with Injection Molding Machine Mold

-

What Are the Essential Components of Plastic Injection Machine Parts?

-

2025 Trends in Overmolding Injection Molding: How to Choose the Best Solutions for Global Sourcing

-

Understanding the Cost of Injection Moulding Machines: A Comprehensive Guide for Manufacturers

Submit a quote request or book a design consultation

Plastimold Products is an end-to-end product development and manufacturing team. We provide product design, engineering, prototyping, tooling, plastic injection molding, assembly, packaging and fulfillment. We work with any size company from start-ups to enterprises from all around the world.

I have a product I want to manufacture

I have a product that is already designed and now needs to be manufactured.

I need a manufacturer to optimize my product for injection molding, help choose the correct material, and manage the product production.

I have tooling that I want to transfer or modify, or I need to produce new tooling.

I need design and engineering support

I have a product concept that I want to be designed and brought to market.

I have a product that needs to be reviewed, improved or DFM’ed.

I am looking for a manufacturer to provide an end-to-end solution, from design and development to inventory, marketing, and sales.

©2022 Plastimold Products - Privacy policy - Terms and Conditions