Top Tips for Successful Polyethylene Injection Molding Techniques

In the realm of manufacturing, polyethylene injection molding has emerged as a pivotal technique, driving innovation and efficiency across various industries. According to Dr. James Anderson, a leading expert in polymer processing, "Mastering the subtleties of polyethylene injection molding can significantly enhance product quality and production speed." This highlights the necessity for industry professionals to adopt successful strategies that optimize the molding process while maintaining the integrity of the final product.

The complexities of polyethylene injection molding require a deep understanding of material properties and processing conditions. Factors such as temperature control, injection speed, and cooling times can profoundly affect the outcomes, making it essential for practitioners to leverage best practices to navigate these challenges. As companies increasingly turn to polyethylene for its versatility and reliability, employing effective techniques becomes crucial in enhancing operational efficiency and reducing waste.

Adopting successful polyethylene injection molding techniques not only contributes to superior product performance but also fosters sustainable manufacturing practices. By focusing on quality control and process optimization, businesses can meet the rising demand for high-performance polyethylene components while adhering to environmental standards. Therefore, staying informed about the latest advancements and insights in polyethylene injection molding is vital for any organization aiming to thrive in this competitive landscape.

Understanding Polyethylene and Its Properties for Injection Molding

Polyethylene (PE) is a versatile thermoplastic widely utilized in the injection molding industry due to its favorable properties. This polymer is characterized by its excellent chemical resistance, low-density structure, and flexibility, making it suitable for various applications from packaging to automotive components. According to the Plastics Industry Association, polyethylene accounts for approximately 30% of the total global plastic production, reflecting its critical role in numerous sectors. With a melting point ranging from 120°C to 180°C, different grades of polyethylene can be employed to enhance strength and impact resistance, addressing diverse engineering requirements.

Understanding the properties of polyethylene is crucial for optimizing injection molding processes. Low-Density Polyethylene (LDPE) exhibits great elasticity and toughness, while High-Density Polyethylene (HDPE) offers increased rigidity and density. Reports indicate that HDPE is often preferred for applications requiring durability, such as industrial containers and piping systems. According to a study by Smithers Pira, the injection molding segment of the polyethylene market is projected to grow by 4.5% annually, driven by the increasing demand for lightweight and durable materials in automotive and consumer goods. By leveraging the unique properties of polyethylene and refining molding techniques, manufacturers can achieve enhanced performance and efficiency in their production lines.

Polyethylene Injection Molding Properties

Key Equipment and Machinery for Efficient Polyethylene Injection Molding

When it comes to polyethylene injection molding, selecting the right equipment and machinery is crucial for achieving high efficiency and product quality. The main components involved in this process include injection molding machines, molds, and auxiliary equipment. Injection molding machines, which can be categorized into hydraulic, electric, and hybrid types, each offer unique advantages. Hydraulic machines are popular for their robust performance in producing large parts, while electric machines provide precision and energy efficiency, making them ideal for intricate designs.

Molds play a pivotal role in determining the final product’s quality and dimensional accuracy. Investing in high-quality molds made from durable materials such as steel or aluminum is essential for long-term production runs. The design of the mold must also facilitate effective cooling, as this impacts cycle times significantly. Auxiliary equipment such as temperature controllers, dryers, and conveyors enhance the overall efficiency of the molding process. By ensuring that all components are well-integrated and functioning optimally, manufacturers can streamline their operations and improve production consistency while minimizing waste.

Employing the right combination of machinery and equipment not only boosts productivity but also enhances the overall quality of polyethylene products, making it a key consideration in the injection molding process.

Essential Techniques to Optimize Injection Molding Performance

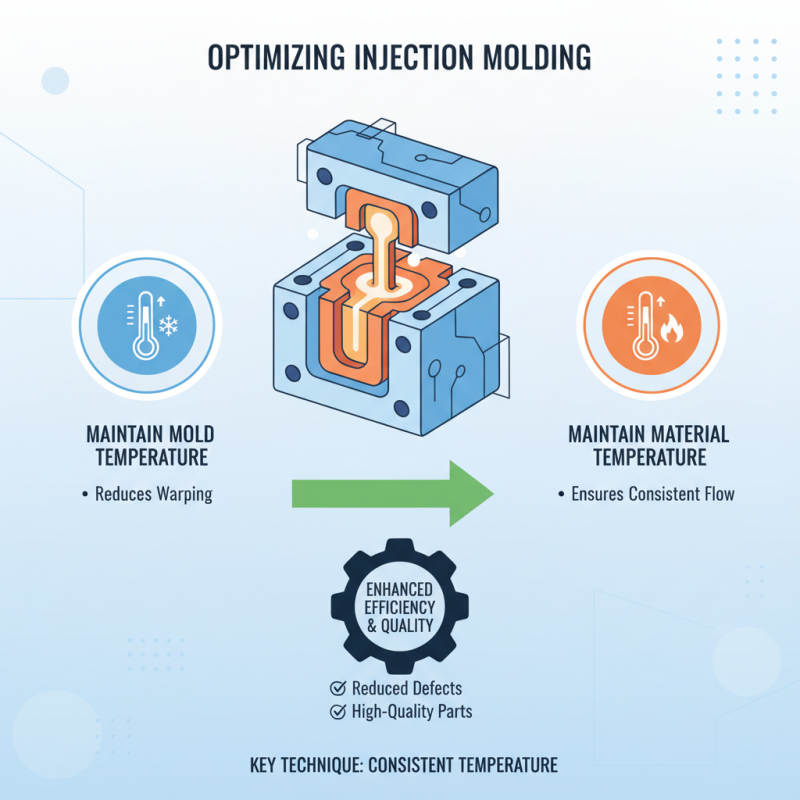

To optimize injection molding performance, it is crucial to focus on several key techniques that enhance the efficiency and quality of the final product. Properly maintaining the temperature of both the mold and the material is essential in achieving optimal flow characteristics. A consistent temperature helps reduce defects such as warping and inconsistent part dimensions, ensuring that each injection cycle yields high-quality results.

Another vital factor is the speed of injection. Adjusting the injection speed can significantly affect the quality of the molded part. A slower injection speed may help in achieving better filling of complex geometries and reduce turbulence, while a faster speed can be advantageous for producing thinner parts. It is essential to find a balance that works best for the specific polyethylene material being used.

Additionally, regular maintenance of equipment and molds can greatly improve performance by minimizing downtime and ensuring precise operation. Implementing a regular cleaning schedule and inspecting for wear or damage can prevent issues that may arise during production. By focusing on these techniques, manufacturers can enhance their polyethylene injection molding processes, leading to consistent product quality and greater efficiency.

Common Challenges in Polyethylene Injection Molding and Solutions

Polyethylene injection molding is a widely used manufacturing process, but it comes with its own set of challenges. One common issue is the occurrence of warping and shrinkage, which can lead to dimensional inaccuracies in the final product. This often arises from the rapid cooling of the material upon ejection from the mold. To mitigate this, manufacturers can optimize cooling channels and adjust the cooling time based on the part geometry and thickness. Additionally, using a material with an appropriate flow rate can help minimize these defects.

Another significant challenge is managing the consistency and quality of the polyethylene itself. Variations in melt flow index can result in unpredictable processing behavior and final product discrepancies. Implementing strict quality control measures and thoroughly testing raw materials before use is essential. Furthermore, ensuring that the equipment is well-maintained and calibrated can help in achieving a more uniform melt, thereby reducing the likelihood of defects and improving overall mold consistency. By addressing these challenges with proactive strategies, manufacturers can enhance the efficiency and quality of their polyethylene injection molding processes.

Best Practices for Quality Control in Polyethylene Injection Products

Quality control in polyethylene injection molding is critical to ensuring that products meet both performance and safety standards. According to a report by the Society of Plastics Engineers, approximately 70% of defects in molded polyethylene products can be traced back to variations in the injection molding process. This underlines the necessity of maintaining strict quality control measures throughout production.

One best practice involves the implementation of real-time monitoring systems to track critical process parameters, such as temperature, pressure, and injection speed. A study by the American Society for Quality found that factories with integrated quality control measures could reduce defects by up to 30%. Additionally, utilizing statistical process control (SPC) methods can help identify trends and anomalies in production, allowing for timely adjustments to avoid defective batches. Adopting a rigorous inspection protocol, including the use of advanced imaging technologies, can further enhance the detection of surface imperfections and dimensional inaccuracies, ultimately leading to higher quality finished products.

Furthermore, training personnel on the importance of quality control and how to spot potential issues early in the process can enhance product quality. Research indicates that organizations investing in employee training related to quality control see a 50% reduction in errors, according to a report from the International Journal of Advanced Manufacturing Technology. Emphasizing continuous improvement and employee engagement in quality initiatives can contribute significantly to the success of polyethylene injection molding operations.

Related Posts

-

The Future of Cost Efficiency in Injection Moulding Machines with Emerging Technologies

-

Why Understanding the Cost of Plastic Injection Molding is Essential for Your Business Growth

-

Unlocking the Future of Manufacturing: The Role of Plastic for Molding in Sustainable Production

-

Revolutionizing Production Efficiency with Advanced Plastic Mold Making Machines in 2023

-

Unlocking Efficiency: The Advantages of Advanced Plastic Injection Molding Machines for Global Buyers

-

7 Best Overmolding Injection Molding Techniques for Enhanced Product Durability

Submit a quote request or book a design consultation

Plastimold Products is an end-to-end product development and manufacturing team. We provide product design, engineering, prototyping, tooling, plastic injection molding, assembly, packaging and fulfillment. We work with any size company from start-ups to enterprises from all around the world.

I have a product I want to manufacture

I have a product that is already designed and now needs to be manufactured.

I need a manufacturer to optimize my product for injection molding, help choose the correct material, and manage the product production.

I have tooling that I want to transfer or modify, or I need to produce new tooling.

I need design and engineering support

I have a product concept that I want to be designed and brought to market.

I have a product that needs to be reviewed, improved or DFM’ed.

I am looking for a manufacturer to provide an end-to-end solution, from design and development to inventory, marketing, and sales.

©2022 Plastimold Products - Privacy policy - Terms and Conditions