What are the Essential Parts of a Plastic Injection Molding Machine

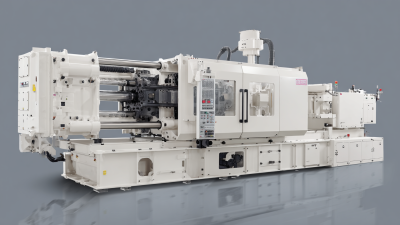

In the realm of manufacturing, plastic injection molding stands out as a crucial process, enabling the creation of complex shapes and components with precision and efficiency. To fully understand the intricacies of this process, one must delve into the essential parts of plastic injection molding machines. These machines consist of various components that work in unison to melt plastic pellets and inject them into molds, ultimately solidifying into the desired shape.

The effectiveness of a plastic injection molding machine is heavily reliant on the functionality and quality of its key parts. From the hopper that feeds raw materials to the heater that ensures proper melting temperatures, each component plays a vital role in the overall operation. Understanding these parts not only aids in optimizing the molding process but also enhances maintenance and troubleshooting efforts. As industries continue to evolve and demand for precision manufacturing increases, a comprehensive knowledge of the fundamental parts of plastic injection molding machines remains essential for engineers and manufacturers alike.

Understanding the Basics of Plastic Injection Molding Machines

Understanding the basics of plastic injection molding machines involves exploring their essential components and how they work together to create molded products. At the heart of any injection molding machine is the injection unit, which is responsible for melting plastic pellets and injecting the molten material into a mold. This unit typically consists of a hopper for feeding raw materials, a barrel where the plastic is heated and melted, and a screw or plunger that injects the material into the mold cavity. These components must work in perfect harmony to ensure accurate and consistent molding.

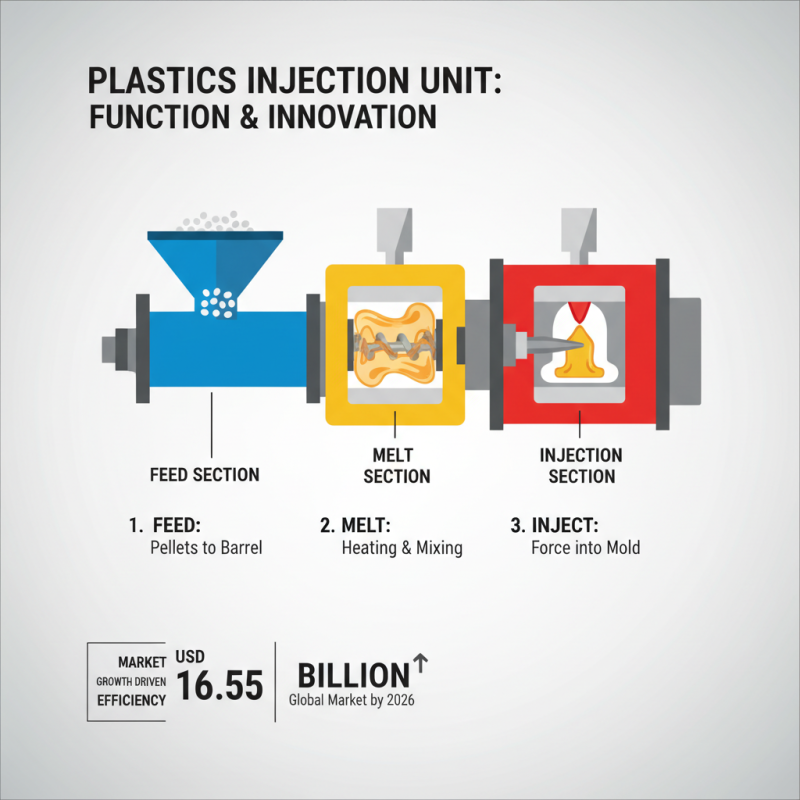

Another critical aspect of plastic injection molding machines is the clamping unit, which securely holds the mold in place during the injection process. This unit applies significant pressure to prevent the mold from opening and ensures that the molten plastic fills the cavity without leakage. The clamping force required depends on the size and complexity of the mold, and it is vital for producing high-quality parts. Additionally, many machines incorporate advanced control systems that monitor and adjust the parameters of the molding process, ensuring optimal performance and reducing waste. Understanding these essential parts and their functions provides a foundation for those interested in the field of plastic injection molding.

What are the Essential Parts of a Plastic Injection Molding Machine

| Component | Description | Function |

|---|---|---|

| Injection Unit | Comprises the barrel, screw, and nozzle for melting and injecting plastic. | Melts the plastic pellets and injects molten plastic into the mold. |

| Clamping Unit | Holds the mold in place during injection and cooling. | Ensures the mold remains closed while plastic is injected and cooled. |

| Mold | The cavity where the molten plastic is shaped into a final product. | Determines the shape and detail of the manufactured part. |

| Hydraulic System | Powers the clamping unit and other movements of the machine. | Provides necessary force for mold closure and ejection of finished parts. |

| Control System | User interface and software for operating and programming the machine. | Controls the machine's operation, including temperature, pressure, and cycle times. |

The Key Components of a Plastic Injection Molding Machine

A plastic injection molding machine is a complex piece of equipment essential for producing a wide range of plastic products. The key components of such machines include the injection unit, clamping unit, and control system. The injection unit is responsible for melting and injecting the plastic material into the mold. Typically, the material is heated to temperatures ranging between 200°C to 250°C for thermoplastics, allowing it to achieve the proper viscosity for effective flow. Research suggests that advancements in screw design and heating elements are contributing to improved melt consistency and reduced energy consumption, with modern machines boasting energy savings of up to 30% compared to older models (MAPP, 2021).

The clamping unit, on the other hand, holds the mold together during the injection phase and opens to eject the finished product. It is critical for ensuring precise mold alignment and maintaining the pressure required for a successful injection cycle. According to industry studies, the mechanical and hydraulic clamp designs in these units are evolving, with toggle mechanisms gaining popularity for their speed and reliability, while hydraulic systems continue to dominate in larger machines due to their power and stability. Furthermore, the control systems integrated into plastic injection molding machines facilitate real-time monitoring and adjustments, enhancing process efficiency and consistency in production output, with automated feedback loops emerging as a standard in modern operations.

Essential Parts of a Plastic Injection Molding Machine

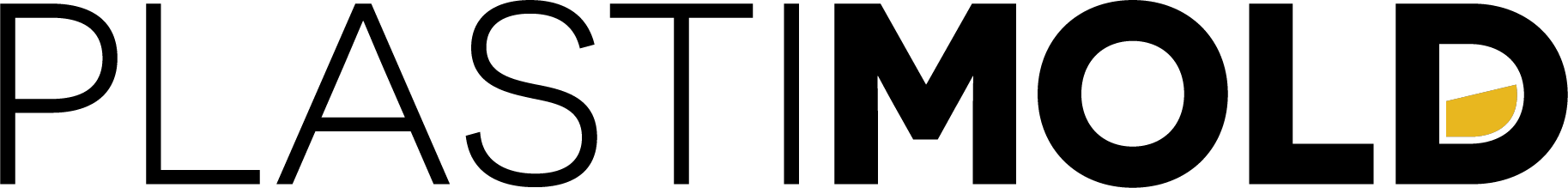

Functionality of Injection Units in Molding Machines

The functionality of injection units in molding machines is a critical aspect of the plastic injection molding process. An injection unit typically consists of several key components, including the feed section, melt section, and injection section, each serving a distinct purpose. The feed section is responsible for transporting plastic pellets into the barrel, where the melting process begins. According to a report by MarketsandMarkets, the global injection molding machine market is projected to reach USD 16.55 billion by 2026, driven largely by advancements in injection unit technology which enhance efficiency in production lines.

The melt section utilizes heaters and a screw mechanism to melt the plastic before it is injected into the mold. This section’s ability to achieve a consistent melt temperature and viscosity is essential for producing high-quality parts. A study published in the Journal of Materials Processing Technology emphasizes that variations in melt temperature can lead to defects in molded products. Proper control of the injection unit is therefore crucial, as it directly impacts cycle times and the overall quality of manufactured components. The injection section then delivers the molten plastic into the mold at high pressure, which is critical for achieving detailed part features and minimizing cycle times.

Hence, the injection unit not only serves the purpose of melting and injecting plastic but also significantly influences the efficiency and output quality of production processes. As industry standards evolve and the demand for precision and speed increases, advancements in injection unit design and technology will continue to play a pivotal role in shaping the future of plastic injection molding.

Importance of Clamping Systems in Plastic Injection Molding

Clamping systems play a crucial role in the operation of plastic injection molding machines. These systems are responsible for holding the mold halves tightly together during the injection process. The primary function of the clamping system is to withstand the immense pressure generated when molten plastic is injected into the mold cavity. A robust clamping system ensures that the mold does not open prematurely, which can lead to defects in the molded part and compromise the quality of the finished product.

Moreover, the efficiency and accuracy of the clamping system significantly impact the overall productivity of the injection molding process. A well-designed clamping system allows for quick mold changes and proper alignment of mold components, reducing downtime and enhancing manufacturing efficiency. Additionally, advanced clamping technologies can help in precise control of the clamping force, offering greater versatility for different types of molds and materials. Overall, the importance of clamping systems in plastic injection molding cannot be overstated, as they are vital for maintaining quality, efficiency, and safety in production.

Cooling and Heating Mechanisms in Injection Molding Machines

In the realm of plastic injection molding, the cooling and heating mechanisms play a pivotal role in determining the efficiency and quality of the final product. Proper temperature control during the injection process is essential, as it affects the viscosity of the material and its flow into the mold.

Studies reveal that maintaining an optimal barrel temperature between 180°C and 200°C significantly improves the flow characteristics of common thermoplastics, leading to reduced cycle times and enhanced precision in mold filling. The cooling system, often involving water-cooled channels, can drastically decrease the cooling time, which is typically between 10 to 30 seconds, depending on the part thickness and complexity.

Efficient heating and cooling not only streamline the production process but also minimize the risk of defects such as warping or incomplete fills. It's recommended to invest in temperature control units that feature precise feedback loops, enabling real-time adjustments based on sensor data. This adaptability can lead to energy savings of up to 20%, according to industry reports.

Tips for optimizing the cooling and heating mechanisms include thoroughly insulating the machine to reduce energy loss and periodically reviewing the temperature distribution across the mold to identify any hotspots. Regular maintenance of these systems can prevent costly downtimes due to inefficiencies, contributing to a more reliable production pipeline.

Related Posts

-

7 Amazing Benefits of Plastic Injection Molding You Didn't Know

-

What Are the Essential Components of Plastic Injection Machine Parts?

-

Custom Solutions for Efficient Injection Molding Machine Molds in Global Industries

-

Top 5 Plastic Types for Molding: Choosing the Best for Your Projects in 2023

-

Understanding the Essential Functions of Plastic Injection Machine Parts in Modern Manufacturing

-

Cost of Plastic Injection Molding Explained How to Save on Production Costs

Submit a quote request or book a design consultation

Plastimold Products is an end-to-end product development and manufacturing team. We provide product design, engineering, prototyping, tooling, plastic injection molding, assembly, packaging and fulfillment. We work with any size company from start-ups to enterprises from all around the world.

I have a product I want to manufacture

I have a product that is already designed and now needs to be manufactured.

I need a manufacturer to optimize my product for injection molding, help choose the correct material, and manage the product production.

I have tooling that I want to transfer or modify, or I need to produce new tooling.

I need design and engineering support

I have a product concept that I want to be designed and brought to market.

I have a product that needs to be reviewed, improved or DFM’ed.

I am looking for a manufacturer to provide an end-to-end solution, from design and development to inventory, marketing, and sales.

©2022 Plastimold Products - Privacy policy - Terms and Conditions