Cost of Plastic Injection Molding Explained How to Save on Production Costs

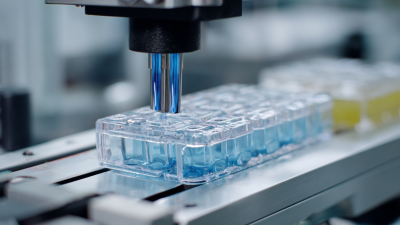

In the competitive landscape of manufacturing, understanding the cost of plastic injection molding is crucial for businesses aiming to enhance their production efficiency and profitability. According to industry expert Dr. Emily Carter, a leading authority in plastic manufacturing processes, "A deep comprehension of the cost factors in plastic injection molding can significantly reduce waste and improve overall production margins." This insight underscores the importance of meticulous analysis in the injection molding process, where costs can vary dramatically based on materials, design complexity, and production volume.

As companies strive to innovate while keeping expenses in check, identifying strategies to save on production costs becomes paramount. By examining the components that contribute to the cost of plastic injection molding, such as tooling, labor, and material selection, businesses can tailor their processes to achieve optimal financial performance. Understanding these cost implications not only aids in smarter budgeting but also paves the way for strategic investments that drive long-term success. Ultimately, mastering the economics of plastic injection molding equips manufacturers to navigate market demands with agility and foresight.

Understanding Plastic Injection Molding Costs

Understanding the costs associated with plastic injection molding is essential for businesses looking to optimize their production processes. The primary factors influencing these costs include material selection, machine operation, and tooling expenses. Material costs can vary significantly based on the type of resin used, with some materials being more expensive than others. Additionally, the machine's operational efficiency and the complexity of the mold design play crucial roles in determining overall expenses. A well-planned design can minimize the amount of scrap material and reduce cycle times, ultimately lowering costs.

Tips: To save on production costs, consider investing in high-quality molds that may have a higher initial cost but offer longevity and durability. This investment can lead to fewer replacements and repairs, ultimately balancing out expenditures over time. Furthermore, collaborating closely with your suppliers can yield discounts on bulk material purchases, making it worthwhile to explore various options for material sourcing.

Another effective strategy is to optimize production runs by reducing the number of changeovers. This can be achieved by standardizing product sizes and designs, which helps streamline the production process. Additionally, utilizing advanced software for process simulation can identify potential bottlenecks and inefficiencies before they occur, allowing for more informed decisions that contribute to cost savings in the long run.

Key Factors Influencing Production Expenses

When considering the costs associated with plastic injection molding, several key factors directly influence production expenses. The design complexity of the part plays a pivotal role; intricate designs can lead to higher tooling costs and longer cycle times. Simplifying the design, where possible, can significantly mitigate these expenses without sacrificing quality. It's crucial to engage in thorough design optimization to ensure that the final product meets specifications while being cost-effective to produce.

Another critical factor is the choice of materials. Different plastics have varying costs and properties that can affect the overall production budget. Selecting more economical materials without compromising on performance can help reduce expenses. Additionally, the volume of production is a determinant; larger runs often benefit from economies of scale, lowering the cost per unit. Strategically planning production schedules to maximize efficiency can optimize costs, ensuring that the manufacturing process remains both effective and affordable.

Effective Strategies to Reduce Molding Costs

When it comes to minimizing the costs associated with plastic injection molding, effective strategies can make a significant difference in the overall expenses. One key approach is to optimize the design of the molded parts. Simplifying designs can reduce machining and material costs, as well as minimize the complexity involved in the molding process. Implementing features such as uniform wall thickness and eliminating unnecessary undercuts can streamline production and decrease cycle times, leading to substantial savings.

Another essential strategy involves choosing the right materials for the job. By researching and selecting cost-effective alternatives that still meet performance requirements, manufacturers can significantly cut down on material costs. Additionally, bulk purchasing of materials can leverage economies of scale, further reducing expenses. Regularly reviewing supplier contracts and exploring options for more competitive pricing can also lead to better material selection and reduced overall costs in injection molding production.

Comparing Costs: In-House vs. Outsourcing Production

When considering production costs for plastic injection molding, one of the primary decisions is whether to manufacture in-house or outsource to a third-party supplier. According to a recent industry report by the Plastics Industry Association, organizations that choose to outsource their production can save anywhere from 20% to 40% on overall costs. This can be attributed to reduced labor expenses, lower overhead, and the ability to leverage suppliers' established capabilities and technologies.

In-house production, while offering greater control over quality and timelines, often requires a significant initial investment in machinery, facilities, and skilled labor. An analysis from a 2022 report by Mordor Intelligence found that the average startup cost for an in-house injection molding facility can range between $250,000 to over $1 million, depending on scale and equipment sophistication. For smaller businesses or startups, these financial burdens can be prohibitive, making outsourcing an attractive option.

However, the choice between in-house and outsourcing isn't solely based on cost. Factors like production volume, product complexity, and time-to-market also play a critical role. For instance, companies focusing on high-volume production and standard parts may benefit from investing in their own tools and machinery, while those needing rapid prototyping might find outsourcing to be the more efficient and flexible solution. According to a study by Deloitte, nearly 70% of manufacturers reported that the decision to outsource or manufacture in-house significantly affects their overall competitiveness in the market.

Cost of Plastic Injection Molding Explained: How to Save on Production Costs - Comparing Costs: In-House vs. Outsourcing Production

| Production Method | Initial Setup Cost ($) | Material Cost per Unit ($) | Labor Cost per Unit ($) | Production Time per Unit (hrs) | Total Cost per Unit ($) |

|---|---|---|---|---|---|

| In-House Production | 15,000 | 0.50 | 0.30 | 0.1 | 1.20 |

| Outsourcing Production | 5,000 | 0.70 | 0.20 | 0.2 | 1.60 |

| Average Cost (In-House) | - | 0.50 | 0.30 | 0.1 | 1.20 |

| Average Cost (Outsourcing) | - | 0.70 | 0.20 | 0.2 | 1.60 |

Long-Term Savings: Investing in Quality and Efficiency

Investing in quality and efficiency for plastic injection molding can lead to substantial long-term savings. According to a report from the Society of Plastics Engineers, high-quality molds can last 50% longer than their lower-cost counterparts, thereby reducing replacement and repair costs over time. When a company opts for durable materials during the molding process, they not only ensure superior product quality but also minimize the risk of defects that often lead to rework and wastage. This mindset is critical in an industry where production errors can account for up to 20% of total costs, as reported in the Plastics Market Watch.

Tips: To enhance efficiency, consider implementing advanced simulation software for mold design. This can streamline the prototyping phase, allowing for adjustments before physical production starts, which mitigates potential issues. Additionally, investing in automation can speed up production cycles while maintaining quality standards, further driving down overall costs associated with labor and production time.

Moreover, conducting thorough supplier evaluations is essential. Data from the National Association of Manufacturers indicates that companies that assess their suppliers regularly are 30% more likely to remain within their budget. By building relationships with reliable suppliers who prioritize high-quality materials and efficient processes, businesses can ensure that they reinforce their own commitment to producing exceptional products with reduced long-term expenses.

Related Posts

-

Why Understanding the Cost of Plastic Injection Molding is Essential for Your Business Growth

-

Exploring Alternative Methods to Automotive Injection Molding for Efficient Production

-

Top 10 Benefits of Automotive Injection Molding You Need to Know

-

Revolutionizing Production Efficiency with Advanced Plastic Mold Making Machines in 2023

-

How to Optimize Plastic Overmolding for Superior Product Durability and Performance

-

2025 Trends in Overmolding Injection Molding: How to Choose the Best Solutions for Global Sourcing

Submit a quote request or book a design consultation

Plastimold Products is an end-to-end product development and manufacturing team. We provide product design, engineering, prototyping, tooling, plastic injection molding, assembly, packaging and fulfillment. We work with any size company from start-ups to enterprises from all around the world.

I have a product I want to manufacture

I have a product that is already designed and now needs to be manufactured.

I need a manufacturer to optimize my product for injection molding, help choose the correct material, and manage the product production.

I have tooling that I want to transfer or modify, or I need to produce new tooling.

I need design and engineering support

I have a product concept that I want to be designed and brought to market.

I have a product that needs to be reviewed, improved or DFM’ed.

I am looking for a manufacturer to provide an end-to-end solution, from design and development to inventory, marketing, and sales.

©2022 Plastimold Products - Privacy policy - Terms and Conditions