How to Choose the Best Plastic Injection Molding Machine for Your Needs

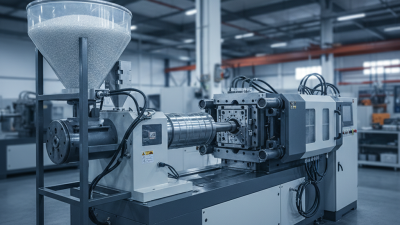

In the ever-evolving world of manufacturing, the choice of a plastic injection molding machine can significantly impact production efficiency and product quality. As noted by industry expert Dr. Emily Zhang, a leading authority in plastic processing technology, "Selecting the right plastic injection molding machine is crucial to achieving not only optimal output but also maintaining the integrity of the final product." With various factors to consider, such as machine size, clamping force, and control systems, making an informed decision can feel daunting.

When delving into the complexities of plastic injection molding machines, it's essential to assess the specific needs of your production line. Understanding the materials you'll be working with, the types of products you aim to produce, and the desired cycle times are critical components of this decision-making process. By carefully evaluating these factors, you can select a machine that not only meets your current demands but also accommodates future growth.

Ultimately, choosing the best plastic injection molding machine is more than just a financial investment; it's a strategic decision that can influence your operation's long-term success. By prioritizing your unique requirements and leveraging insights from industry experts, you can ensure that your choice aligns with your business goals and manufacturing demands.

Understanding Plastic Injection Molding Machines: Key Concepts

Understanding plastic injection molding machines is essential for making informed choices that align with your manufacturing needs. These machines operate on a simple principle: molten plastic is injected into a mold, where it cools and solidifies into a final product. Key concepts include clamping force, injection unit design, and the type of control systems used in these machines. Clamping force is critical as it holds the mold closed during injection and impacts the quality of the finished piece. Understanding these components will help you select a machine that suits your production requirements.

Tip: When assessing clamping force, consider the size and complexity of the parts you intend to produce. For larger items or intricate designs, a higher clamping force may be necessary to prevent defects during the molding process.

The injection unit design also plays a vital role in efficiency and product quality. Variations exist, such as reciprocating screw or plunger designs, each offering different advantages. Additionally, the control systems—be it hydraulic, electric, or hybrid—impact the precision and energy consumption of the machine. An electric machine, for example, typically offers higher precision and lower energy costs.

Tip: Evaluate your production volume and part complexity while choosing the injection unit and control system to ensure that you achieve an optimum balance of cost, performance, and sustainability.

Plastic Injection Molding Machine Tonnage Requirements

Assessing Your Production Needs and Requirements

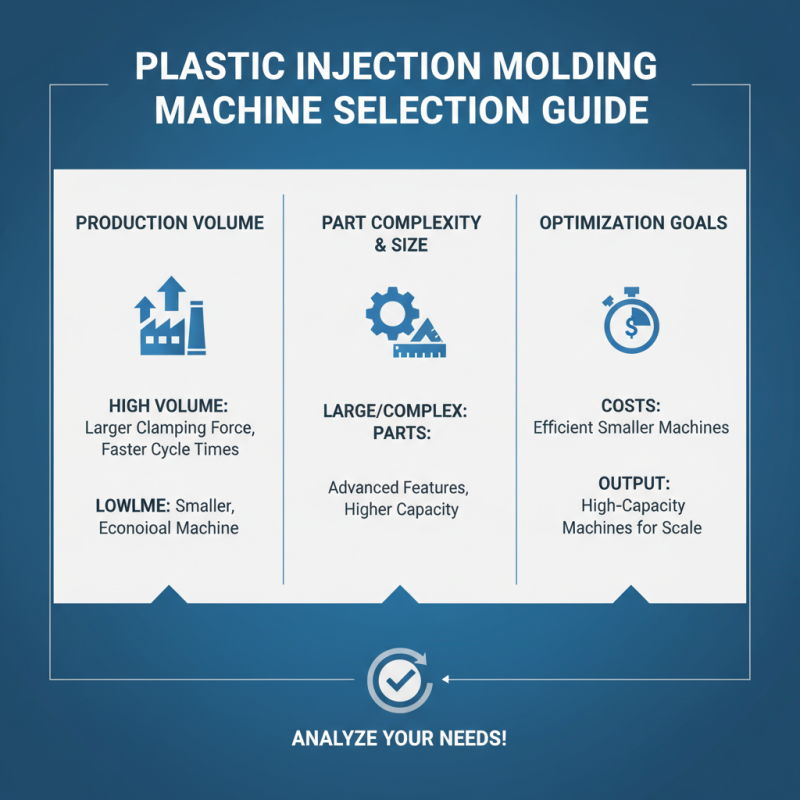

When selecting a plastic injection molding machine, assessing your production needs and requirements is crucial. Start by analyzing your production volume. If high-volume production is necessary, a machine with a larger clamping force and higher cycle times will likely be more suitable. Conversely, for lower production demands, a smaller, more economical machine can optimize costs while meeting your output needs. Additionally, consider the complexity and size of the parts you wish to produce. Larger or intricately designed components may require advanced features and capabilities in your injection molding machine.

Furthermore, it is important to evaluate the types of materials you plan to use as different plastics may require varying processing temperatures and injection pressures. Your machine choice should accommodate these specifications to ensure efficient and effective production. Pay attention to the ease of operation and maintenance, as these factors can greatly affect your production workflow. Finally, think about the potential for future growth. Investing in a machine that offers flexibility and adaptability can cater to changing production demands and technological advancements, making it a worthwhile long-term investment.

Evaluating Machine Specifications and Features

When selecting the ideal plastic injection molding machine, a comprehensive evaluation of its specifications and features is crucial. Key machine specifications to consider include clamping force, shot size, and injection speed. Clamping force is essential as it determines the ability of the machine to hold the mold tightly together during injection; inappropriate force can lead to defects in the final product. Similarly, shot size should align with your production requirements, ensuring that the machine can produce parts within the desired weight and dimensions.

Tip: Always assess your production volume and part complexity to ascertain the correct shot size before making a decision.

Furthermore, injection speed and cycle time directly affect production efficiency. A machine with high injection speed can significantly reduce cycle time, improving overall productivity. It’s important to evaluate the machine's energy consumption as well since more energy-efficient models can reduce operating costs in the long run.

Tip: Consider machines with advanced control systems, which can enhance precision and reduce waste, ultimately saving both time and resources during the manufacturing process.

Comparing Different Brands and Models in the Market

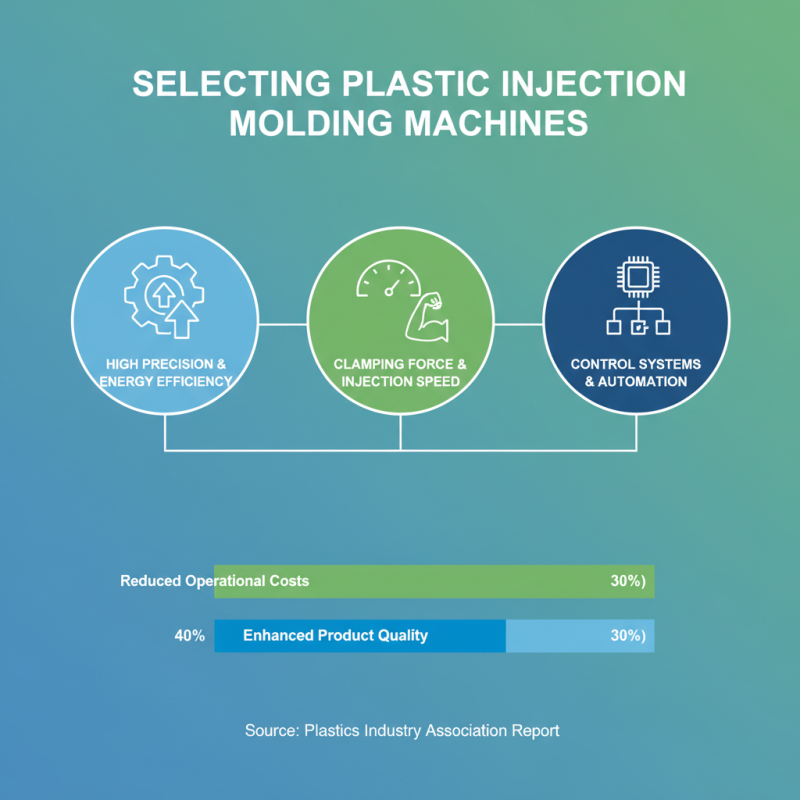

When selecting the best plastic injection molding machine for your needs, it is essential to consider various brands and models available in the market. Each manufacturer offers distinct features that cater to specific production requirements. For instance, a recent industry report from the Plastics Industry Association indicates that machines designed for high precision and energy efficiency are becoming increasingly sought after, as they reduce operational costs and enhance product quality. Buyers should assess the machine's clamping force, injection speed, and control systems to ensure they align with their production volumes and complexity.

Furthermore, it is crucial to evaluate the support and service offerings from different brands. According to a study conducted by Grand View Research, brands that provide reliable customer service and readily available spare parts tend to achieve higher customer satisfaction rates. In addition, various models incorporate advanced technology solutions, such as automation and real-time monitoring, which can significantly improve efficiency and reduce downtime in manufacturing processes. By comparing these aspects across different brands and models, manufacturers can make more informed decisions that align with their operational goals and ensure long-term productivity.

Considering Budget, Maintenance, and After-Sales Support Options

When selecting a plastic injection molding machine, considering budget, maintenance, and after-sales support is crucial for maximizing your investment. According to industry reports, around 30% of manufacturers experience challenges related to machine upkeep, leading to increased operational costs. Therefore, assessing the maintenance needs of the machine you choose can significantly impact its long-term value. Opt for models with readily available spare parts and straightforward maintenance procedures to minimize unexpected downtime and costs.

Tip: Evaluate the total cost of ownership rather than just the upfront price. This includes maintenance costs, energy efficiency, and potential productivity losses if the machine breaks down frequently. A machine that seems affordable at first may lead to higher expenses in the long run if it requires constant repairs.

After making your selection, prioritize manufacturers that offer comprehensive after-sales support. Research indicates that 70% of industry professionals value ongoing technical assistance as a key factor in their purchase decision. Ensure that the vendor provides adequate training, a robust warranty, and technical support availability to address any issues that may arise post-purchase. This support can significantly enhance your operational efficiency and prolong the machine's life cycle.

Tip: Look for reviews or case studies illustrating other users' experiences with after-sales support. Positive feedback can be a strong indicator of reliable service and can help you avoid future headaches.

Related Posts

-

Custom Solutions for Efficient Injection Molding Machine Molds in Global Industries

-

Discover the Science Behind Plastic for Molding: Transforming Ideas into Reality

-

Unlocking Efficiency: The Advantages of Advanced Plastic Injection Molding Machines for Global Buyers

-

7 Best Overmolding Injection Molding Techniques for Enhanced Product Durability

-

What are the Essential Parts of a Plastic Injection Molding Machine

-

5 Reasons Insert Molding is Revolutionizing Modern Manufacturing

Submit a quote request or book a design consultation

Plastimold Products is an end-to-end product development and manufacturing team. We provide product design, engineering, prototyping, tooling, plastic injection molding, assembly, packaging and fulfillment. We work with any size company from start-ups to enterprises from all around the world.

I have a product I want to manufacture

I have a product that is already designed and now needs to be manufactured.

I need a manufacturer to optimize my product for injection molding, help choose the correct material, and manage the product production.

I have tooling that I want to transfer or modify, or I need to produce new tooling.

I need design and engineering support

I have a product concept that I want to be designed and brought to market.

I have a product that needs to be reviewed, improved or DFM’ed.

I am looking for a manufacturer to provide an end-to-end solution, from design and development to inventory, marketing, and sales.

©2022 Plastimold Products - Privacy policy - Terms and Conditions