Top 10 Benefits of Automotive Injection Molding You Need to Know

In the dynamic landscape of the automotive industry, the manufacturing processes that enhance efficiency and product quality are paramount. One such process gaining recognition is automotive injection molding. This innovative technique allows manufacturers to create complex and high-precision components that meet the rigorous demands of modern vehicles. According to Dr. Emily Smith, an expert in automotive manufacturing technologies, "Automotive injection molding not only reduces production time but also elevates the quality and durability of automotive parts."

As the industry continues to evolve, understanding the benefits of automotive injection molding becomes essential for manufacturers aiming to stay competitive. From cost reduction to design flexibility, the advantages of this method are multi-faceted. The integration of advanced materials and technologies further enhances its application, making it a cornerstone in the production of lighter, more efficient vehicles. This article will delve into the top ten benefits of automotive injection molding, shedding light on why it is a crucial element in the future of automotive manufacturing.

Overview of Automotive Injection Molding Technology

Automotive injection molding technology is a transformative process within the automotive industry, significantly enhancing the efficiency and quality of vehicle parts production. This method involves injecting molten plastic into a mold, allowing it to solidify into the desired shape once cooled. This precision manufacturing technique is especially beneficial for creating intricate components that require high dimensional accuracy, which is crucial for parts such as dashboard panels, exterior trims, and other interior elements.

One of the critical advantages of injection molding in automotive applications is its ability to produce large quantities of parts in a short timeframe, optimizing production throughput. Additionally, this technology allows for the incorporation of various materials, including reinforced plastics that can provide enhanced durability and impact resistance. The versatility in material choice also enables manufacturers to create lightweight components, contributing to overall vehicle efficiency and performance. The repeatability of the injection molding process ensures consistent quality across production runs, making it a preferred choice for automotive manufacturers aiming for reliability and precision in their products.

Enhanced Design Flexibility in Automotive Parts Production

The adoption of automotive injection molding has revolutionized the design flexibility in the production of automotive parts. This advanced manufacturing process allows for intricate designs that were previously unattainable with traditional techniques. According to the American Society for Precision Engineering, injection molding is capable of producing complex geometries and thin-walled components, making it a preferred choice for automotive manufacturers seeking both innovation and efficiency. With the ability to create parts with varying wall thicknesses and detailed features, designers can push the limits of creativity without compromising the integrity or performance of the components.

Furthermore, the enhanced design flexibility offered by injection molding not only facilitates the creation of lightweight automotive components but also contributes to overall cost savings. A study by the Society of Automotive Engineers indicates that lighter components lead to improved fuel efficiency, which is becoming increasingly critical as regulatory standards tighten. By employing injection molding, manufacturers can rapidly prototype and iterate designs, drastically reducing the time from concept to production. The efficiency of this process has been shown to decrease material waste by up to 30%, aligning with the industry's ongoing push towards sustainability and resource optimization. Thus, the enhanced design capabilities afforded by automotive injection molding represent a significant advancement in automotive engineering, enabling manufacturers to meet evolving consumer demands and regulatory pressures with greater agility.

Top 10 Benefits of Automotive Injection Molding You Need to Know

| Benefit | Description | Impact on Production | Examples of Use |

|---|---|---|---|

| Design Flexibility | Allows complex shapes and designs that are difficult to achieve with other methods. | Reduces engineering time and costs. | Car dashboards, panels, and covers. |

| Cost Efficiency | High production rates lead to lower per-unit costs. | Improves profit margins for manufacturers. | Bumper covers and trim pieces. |

| Material Variety | Compatible with a wide range of materials, including thermoplastics and metals. | Facilitates innovation in product design. | Components in hybrid and electric vehicles. |

| Precision and Accuracy | High tolerance levels in production ensure parts fit together perfectly. | Enhances overall vehicle quality. | Precision-engineered functional parts. |

| Reduced Waste | Efficient material usage leads to less scrap and waste. | Supports environmentally friendly manufacturing practices. | Sustainable automotive components. |

| Shorter Lead Times | Faster setup and production cycles compared to traditional methods. | Quickens time to market for new models. | Rapid prototyping of new designs. |

| Enhanced Strength | Parts produced are generally stronger and more durable. | Increases vehicle safety and longevity. | Structural components like chassis parts. |

| Layered Manufacturing | Supports multi-layered components for enhanced functionality. | Reduces assembly complexity. | Complex air ducts and heating systems. |

| Customization | Injection molding allows for easy customization of parts. | Meets specific customer requirements more effectively. | Custom interior features and designs. |

Cost Efficiency through Reduced Material Waste and Labor

Automotive injection molding is increasingly recognized for its cost efficiency, particularly through the reduction of material waste and labor expenses. This manufacturing process allows for the precise shaping of components, resulting in minimal excess material. Traditional manufacturing methods often produce significant waste, as they rely on cutting and shaping materials in ways that can lead to residual scraps. In contrast, injection molding utilizes only the necessary amount of plastic, which is injected into molds under high pressure. This not only conserves raw materials but also promotes more sustainable practices in the automotive industry.

In addition to material savings, automotive injection molding optimizes labor efficiency. The automation involved in the injection molding process reduces the need for extensive manual intervention, enabling faster production cycles. By minimizing human error and improving consistency, manufacturers can streamline operations and allocate labor resources more effectively. This automation translates into reduced labor costs, allowing companies to produce high-quality components while focusing their workforce on higher-value tasks. Overall, the cost benefits derived from reduced material waste and labor create a compelling case for the increased adoption of injection molding in automotive manufacturing.

Improved Production Speed and Scalability in Manufacturing

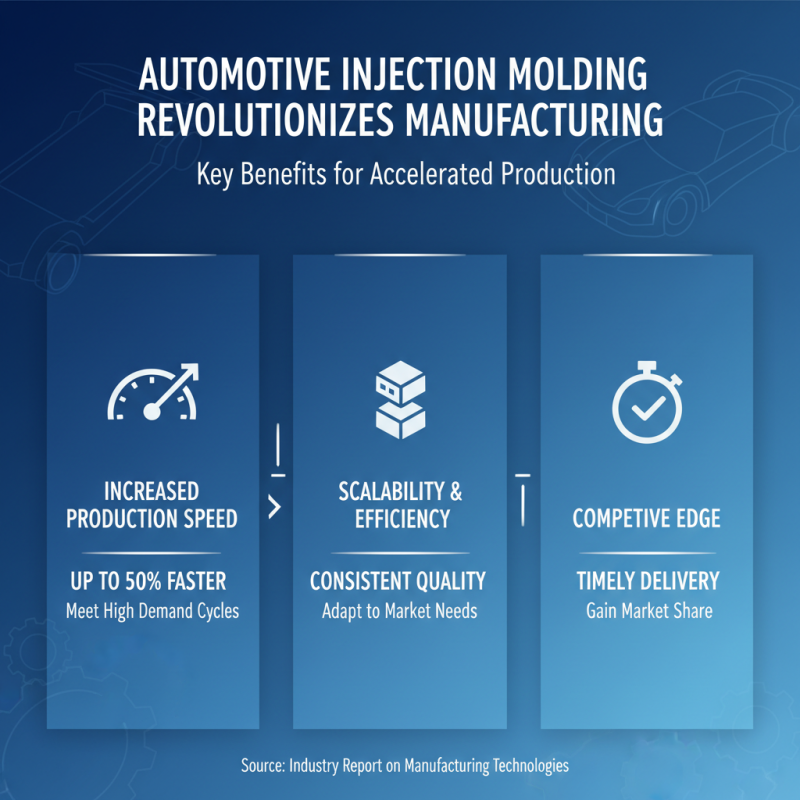

Automotive injection molding has revolutionized manufacturing processes, particularly in terms of production speed and scalability. According to a recent industry report, the adoption of injection molding techniques can increase production efficiency by up to 50%, allowing manufacturers to meet high-demand cycles without compromising on quality. This accelerated manufacturing process is essential in today’s fast-paced automotive industry, where timely delivery of parts can directly influence a company's competitive edge.

Additionally, the scalability of injection molding offers manufacturers the flexibility to easily adjust production volumes according to market demands. A study indicated that companies utilizing advanced injection molding technologies can scale their operations without significant downtime or additional costs. This adaptability not only enhances operational efficiency but also allows for swift responses to consumer trends, ultimately positioning manufacturers ahead of the competition.

**Tips:** To fully leverage the benefits of automotive injection molding, consider investing in state-of-the-art molding machines that incorporate real-time monitoring systems. These systems can optimize production workflows and identify potential bottlenecks before they impact overall efficiency. Furthermore, maintaining a robust inventory of injection molds can facilitate rapid prototyping and testing, enabling quicker transitions from design to production.

Sustainability Benefits of Injection Molding in the Automotive Industry

Sustainability has become a critical concern for the automotive industry,

and injection molding offers several environmental benefits that align with this goal. One significant advantage is the efficient use of materials. Injection molding allows for precise control over the amount of plastic used in production, minimizing waste. By optimizing the design and thickness of parts, manufacturers can not only reduce excess material but also lower their overall carbon footprint.

Moreover, many modern injection molding processes utilize recycled materials, further enhancing the sustainability aspect. By incorporating recycled plastics into production, the automotive industry can decrease its reliance on virgin materials, resulting in less energy consumption and reduced emissions associated with raw material extraction and processing. Additionally, injection molding techniques can facilitate the production of lightweight components, which contribute to fuel efficiency in vehicles.

As automakers seek to comply with stringent emission standards,

the integration of sustainable practices through injection molding becomes paramount.

Related Posts

-

Exploring Alternative Methods to Automotive Injection Molding for Efficient Production

-

7 Best Overmolding Injection Molding Techniques for Enhanced Product Durability

-

Unlocking the Future of Manufacturing: The Role of Plastic for Molding in Sustainable Production

-

Why Understanding the Cost of Plastic Injection Molding is Essential for Your Business Growth

-

Top 7 Import Export Certifications for Best Plastic Injection Molding Machines in 2023

-

Custom Solutions for Efficient Injection Molding Machine Molds in Global Industries

Submit a quote request or book a design consultation

Plastimold Products is an end-to-end product development and manufacturing team. We provide product design, engineering, prototyping, tooling, plastic injection molding, assembly, packaging and fulfillment. We work with any size company from start-ups to enterprises from all around the world.

I have a product I want to manufacture

I have a product that is already designed and now needs to be manufactured.

I need a manufacturer to optimize my product for injection molding, help choose the correct material, and manage the product production.

I have tooling that I want to transfer or modify, or I need to produce new tooling.

I need design and engineering support

I have a product concept that I want to be designed and brought to market.

I have a product that needs to be reviewed, improved or DFM’ed.

I am looking for a manufacturer to provide an end-to-end solution, from design and development to inventory, marketing, and sales.

©2022 Plastimold Products - Privacy policy - Terms and Conditions