Exploring Alternative Methods to Automotive Injection Molding for Efficient Production

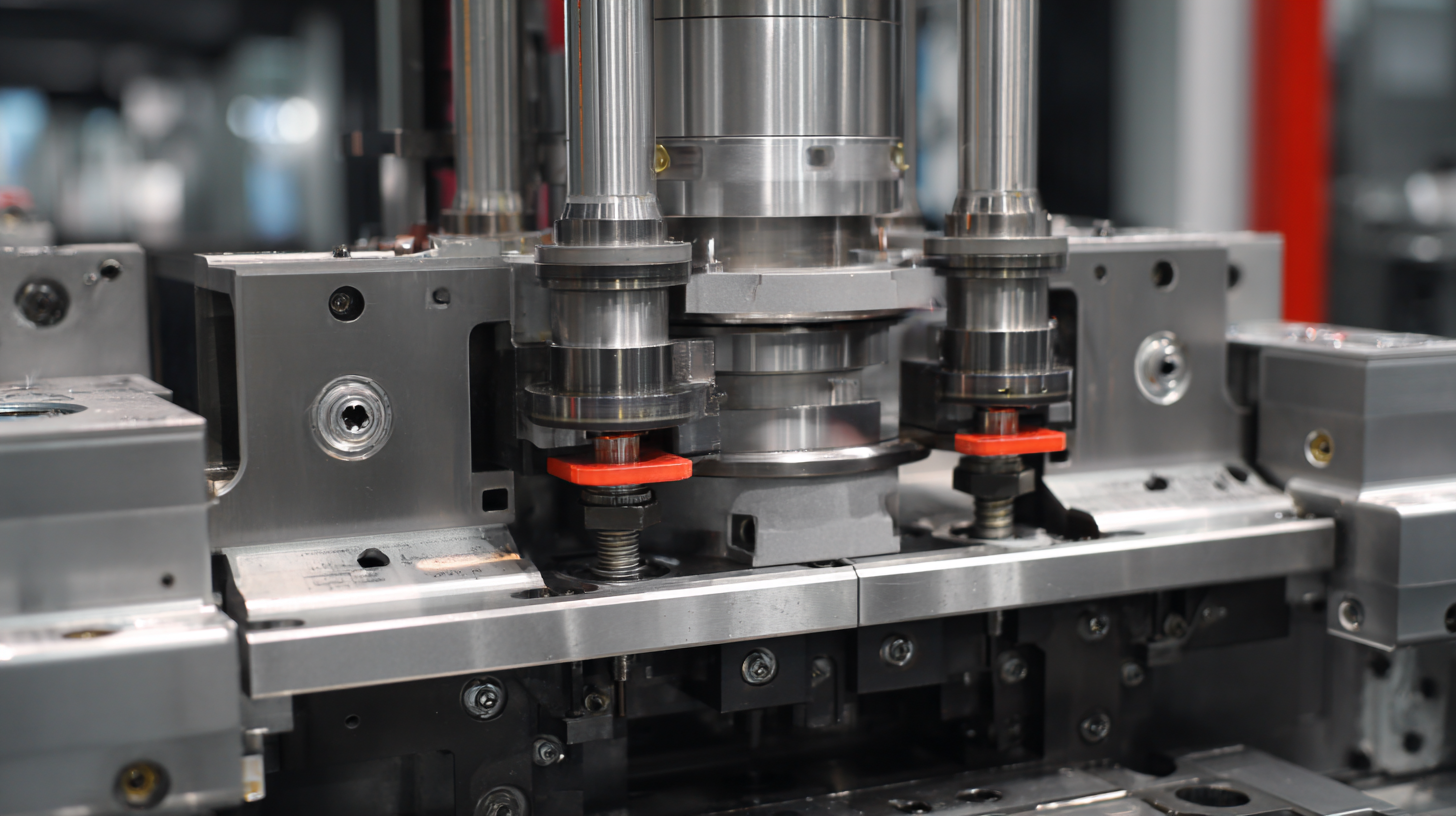

The automotive industry is at a pivotal juncture, where the demand for efficiency and innovation drives manufacturers to explore alternative methods to automotive injection molding. According to a report by Grand View Research, the global automotive injection molding market was valued at USD 31.3 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2022 to 2030. As automakers face challenges related to production costs, material sustainability, and lead times, they are increasingly considering innovative manufacturing techniques that promise enhanced efficiency without compromising quality.

This ultimate guide delves into these alternative methods, evaluating their potential advantages and limitations, and examining how they can align with the evolving demands of the automotive sector. As we navigate through emerging technologies and processes, the future of automotive production may very well depend on the successful integration of these alternatives alongside traditional automotive injection molding.

Innovative Techniques for Streamlining Automotive Component Manufacturing

The automotive industry is witnessing a transformative shift as manufacturers seek innovative techniques to streamline component manufacturing. With the increasing pressure to enhance production efficiency and sustainability, alternative methods to traditional injection molding are becoming more prominent. These advancements not only reduce waste but also optimize energy consumption, aligning with the industry's sustainability goals.

Emerging technologies, such as additive manufacturing and advanced material composites, provide exciting alternatives that can fulfill the growing demand for lightweight and durable automotive components. By leveraging these innovations, manufacturers can respond more effectively to the dynamic market demands while minimizing their environmental footprint. As the focus on green manufacturing intensifies, the integration of these innovative approaches is poised to drive significant growth in the automotive sector, paving the way for a more sustainable future.

Comparative Analysis of Traditional vs. Alternative Molding Methods

The exploration of alternative molding methods in the automotive industry is gaining momentum, particularly in the context of efficiency and sustainability. Traditional injection molding has long been the go-to technique for mass-producing complex parts; however, emerging technologies like 3D printing are challenging this status quo. Recent comparative studies, such as the one evaluating 3D printed denture base materials against conventional methods, reveal significant differences in durability and performance characteristics. This shift towards additive manufacturing highlights its potential to reduce material waste and allow for rapid prototyping, which can be particularly beneficial in the automotive sector where design iterations are frequent.

Moreover, the integration of innovative techniques such as vacuum bagging molding and hybrid fabrication methods demonstrates a broader trend towards combining traditional and digital approaches. These alternatives not only offer enhanced production efficiency but also cater to the growing demand for sustainable practices within manufacturing. As industries, including automotive, strive to reduce their ecological footprint, the adoption of methods that leverage renewable resources and minimize waste will be crucial. The landscape of automotive production is poised for transformation as traditional methods adapt to the pressures of sustainability and technological advancement.

Cost-Effectiveness and Sustainability in Modern Injection Molding

In the fast-evolving automotive industry, the push for cost-effectiveness and sustainability has led manufacturers to explore alternative methods to traditional injection molding. While injection molding has been a staple for producing automotive parts due to its efficiency, the environmental impact and rising material costs have prompted a reevaluation. Embracing materials that are not only lightweight but also recyclable is key in this transition toward greener practices.

Tips for manufacturers include evaluating biodegradable polymers that can maintain performance while minimizing ecological footprints. Additionally, investing in advanced technologies such as 3D printing or hybrid manufacturing processes can significantly reduce waste and energy consumption. By incorporating these innovations, companies can achieve not just economic benefits but also enhance their reputation as sustainable players in the automotive sector.

Furthermore, optimizing the supply chain by sourcing local materials can cut down transportation emissions and costs, thus supporting sustainability goals. Engaging with suppliers who prioritize sustainable practices can also reinforce a commitment to environmentally friendly production. By focusing on cost-effectiveness and sustainability, the automotive sector can effectively lead the way in responsible manufacturing.

Leveraging 3D Printing in the Automotive Production Process

In the automotive industry, the integration of 3D printing is redefining production efficiency and innovation. Traditional injection molding methods are facing challenges in meeting the dynamic needs of automotive design, making way for additive manufacturing technologies. The global market for CAE is projected to reach $7,072.3 million by 2025, growing at a CAGR of 7.9% to hit $12,993.7 million by 2033. This rapid growth signals the industry's shift towards more versatile and efficient production techniques, particularly with metal and polymer materials.

One major advantage of leveraging 3D printing in automotive production is its ability to produce complex geometries that would be difficult or impossible with conventional methods. For instance, 3D-printed prototypes can be tailored to specific automotive requirements, reducing lead times and production costs. As the demand for specialized parts rises, companies focusing on additive manufacturing are set to benefit significantly.

**Tips:**

- Invest in training for engineers and designers in 3D printing technologies to maximize the potential of additive manufacturing.

- Consider pilot projects to explore the viability of 3D printing different components, enabling gradual adoption and scalability in production processes.

As the automotive sector continues evolving, staying ahead of these trends is crucial for maintaining a competitive edge in the market.

Best Practices for Implementing Alternative Molding Solutions in Factories

In the quest for efficiency and innovation in automotive production, exploring alternative molding methods can significantly enhance factory operations. One of the best practices for implementing these solutions is to start with a thorough analysis of the existing manufacturing processes. By identifying bottlenecks and areas that require improvement, manufacturers can select the most suitable alternative molding techniques, such as 3D printing or compression molding, that align with their production goals. This strategic approach ensures that transitions are not only seamless but also tailored to the specific needs of the facility.

Another critical practice is investing in employee training and fostering a culture of adaptability. As new molding technologies often require different skill sets, ensuring that the workforce is well-prepared is essential for maximizing productivity. Encouraging collaboration between teams allows for the sharing of knowledge and experiences, ultimately leading to more innovative solutions. Additionally, engaging in partnerships with technology providers can facilitate better insights into best practices and optimize the implementation of alternative molding solutions. By prioritizing training and collaboration, factories can leverage new methods effectively, driving efficiencies in automotive production.

Submit a quote request or book a design consultation

Plastimold Products is an end-to-end product development and manufacturing team. We provide product design, engineering, prototyping, tooling, plastic injection molding, assembly, packaging and fulfillment. We work with any size company from start-ups to enterprises from all around the world.

I have a product I want to manufacture

I have a product that is already designed and now needs to be manufactured.

I need a manufacturer to optimize my product for injection molding, help choose the correct material, and manage the product production.

I have tooling that I want to transfer or modify, or I need to produce new tooling.

I need design and engineering support

I have a product concept that I want to be designed and brought to market.

I have a product that needs to be reviewed, improved or DFM’ed.

I am looking for a manufacturer to provide an end-to-end solution, from design and development to inventory, marketing, and sales.

©2022 Plastimold Products - Privacy policy - Terms and Conditions